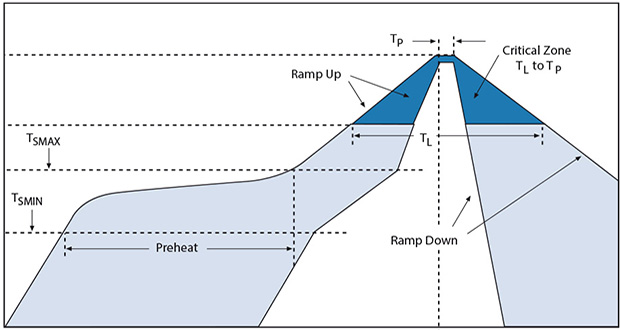

This next stage is when the board temperature enters into the thermal soak area. On some occasions, temperature rise rates, down to one degree per Celsius, can be used. When using infra-red soldering, the temperature rise rate is between 2 and 3 degrees Celsius. If you apply too much heat, the board can be compromised by thermal stress. There are four stages used, as follows: Preheatīring the board to the required temperature. To properly control the temperature of the reflow tunnel will ensure the solder joints are properly attached. The reflow soldering stage consists of several individual steps due to the temperature changes.

Reflow soldering at home manual#

If you need accuracy and manual placement is not an option, use a pick and place machine. Pick and PlaceĪpply the solder paste on the board and then place the components you require. You can use a solder mask and a solder paste machine to apply only to the necessary areas. Only add solder paste to those areas required for soldering. Solder PasteĪpply solder paste to the board that requires soldering. The stages of preparation for reflow soldering include a variety of important steps. In today’s electronic needs, this high-quality style of soldering is reliable and efficient. Pad sizes and varieties of components are easily monitored and controlled during this process. Reflow soldering is commonly used in PCB manufacturing. Use reflow soldering for smaller projects, and wave soldering tackles the larger tasks. Water is then sprayed over the PCB board, cooling the solder and affixing parts in place. This pump creates a solder that can almost be described as a “wave” over the board this sells the board’s components. Wave soldering is done by passing circuit boards over a pan, with a pump, of molten solder. The range for reflow temperature is between 240 and 250 degrees Celsius for a Pb-Free (Sn/Ag) solder. Solder also contains toxins if heated too heavily, so you want to ensure your heat gun is at the correct temperature before starting. A heat gun is a relatively inexpensive method to heat solder paste onto your components and the board however, it still can get quite hot, and thus you need to be careful while handling it. Reflow soldering is done on a smaller scale. When you require bulk soldering, which involves many circuit boards in a short period, wave soldering is the most efficient method. Both have benefits depending on your project. There are two ways of soldering: wave soldering and reflow soldering.

Soldering is very important during the PCB design process it’s the only way to adhere circuits to your board. What is the difference between reflow soldering and wave soldering? Reflow Soldering Have options for repeatable placement for surface mount components.Get a detailed and well-designed printed PCB.Be sure to have a PCB element footprint design.You will require suitable reflow profile conditions.You want to make sure that the reflow soldering process is a success, consider the following: For an Effective Reflow Soldering Process Reflow soldering is a reliable method with very high pitch leads. This secures the electrical components to the circuit board. The board is put through a tunnel with controlled heat to melt the solder paste. Once the solder paste is applied, place the components on the board. You can then use reflow ovens or infrared lamps to produce this high heat-solder individualized solder joints with a hot air pencil. Use controlled heat to reflow the solder paste into a molten state this creates permanent solder joints. Solder paste, a mixture of powdered solder and flux, attaches many small electrical elements to a contact pad.

Reflow soldering is a process that involves attaching surface mount components to a circuit board (PCB).

0 kommentar(er)

0 kommentar(er)